There are many vendors and HW or service suppliers out there. Sometimes the process of choosing the right supplier can be long and tedious especially when the HW item is, on the one hand critical to the system while on the other hand takes up a big portion of the Bill of Materials (BOM). In this post I would like to lay out the different parameters that would impact our vendor selection and this mainly to verify that nothing important is left out when we go ahead and integrate a piece of HW into our system.

Bear in mind that vendor selection is not entirely up to the engineering or the technical teams since there are factors that impact the selection which Supply Chain and Purchasing may define as critical and that would, from the technical aspects, trump any other claim we may raise. To give you the full picture I will simultaneously lay down the technical view of things as well as the Supply Chain’s point of view.

Vendor Selection Stakeholders

It is paramount to mention that there are many functions involved in vendor selection. Without going into too much detail, the following is a list of the main contributors for the selection:

- Technical R&D (System Engineering, Mechanics, Electronics, Physics or any other technical HW discipline, SW in some cases)

- Manufacturing

- Project Management

- Supply Chain & Purchasing

- Finance

- Legal

- Service & Sustain

The Easy Choice

When you require a peculiar piece of HW that only one vendor in the world can manufacture or require some kind of customization that only a handful of vendors could handle, there really isn’t much choice is there? Buy your HW from that vendor and take into account that this particular vendor is going to be a business enabler for your project, so try to keep your relationship with that vendor in the best of terms. BTW, in this specific case the purchasing or acquisition department will label this vendor as “critical vendor” or any other appropriate term while at the same time, if merely for the sake of price negotiation, doing their best to find a second vendor for this particular piece of HW.

Cautionary clause: if you discover that a substantial amount of your HW is either customized or could be manufactured by only a handful of suppliers do a deep and thorough re-evaluation of your requirements, design and implementation. Depending on project complexity, a 10-20% upper limit is a good guideline. Ignore this clause if you are in cutting-edge advanced technologies development such as in high-end semiconductor industry, air-space industry, quantum computing etc. These industries have very specific HW requirements which indeed have only a few suppliers who can manufacture to spec. For example, an EUV machine in the semiconductor industry will have to negotiate with ASML, which in turn, will have to negotiate with Trumpf for the laser unit.

If we address a day-to-day product development or manufacturing, most of the HW we integrate into our system is not one of a kind.

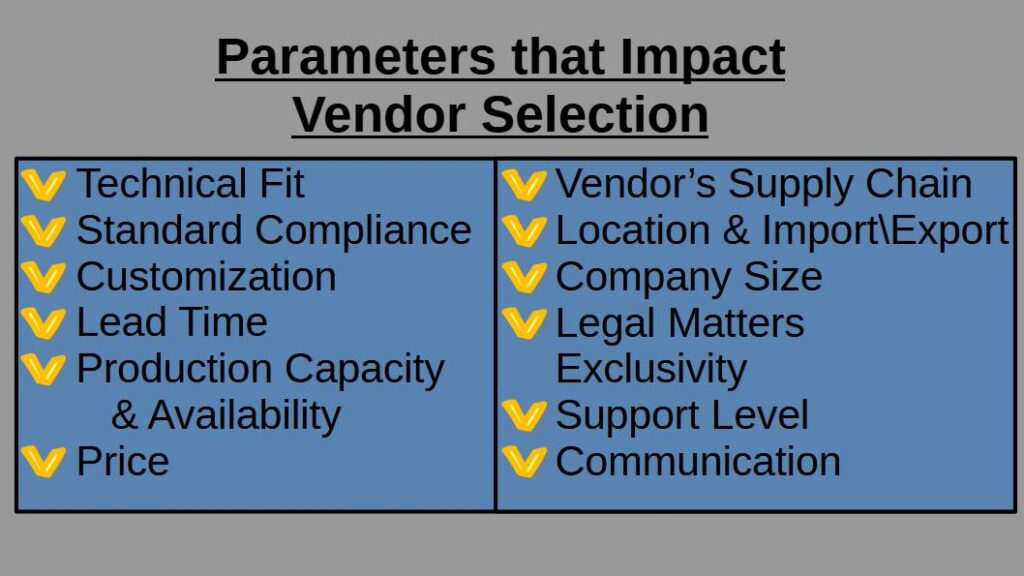

Parameters that Impact Vendor Selection

There are many parameters that would impact our choice of a HW vendor. Here are the details of the main impactors.

Technical Fit

It almost goes without saying but the most important of all is that the piece of HW that we purchase from our chosen vendor will comply with our technical specifications. The reason it only “almost” goes without saying lies in the long stakeholders’ list. We sometimes see cases where the Supply Chain or Purchasing representatives are very dominant and a closely-technical-fit HW vendor is chosen solely because of team dynamics. Obviously, one of the specifications for the product should be target price so that if such or such item costs more than what our budget allows, we have to find a solution for it; either by changing the target-price or by redefining the technical requirements. Either way, when the vendor is chosen the provided items must comply with the most recent technical specifications.

Standard Compliance

If our product has to comply with ISO, RoHS or any other standard a vendor that already complies with this standard has an advantage. Taking a vendor that does not comply with the relevant RoHS version for example will cause a lot of overhead when we come to address our own standard compliance. Sometimes, when the purchasing company is big enough and the vendor is small enough, the purchasing company helps that specific vendor out in the process of receiving the required standard certificate but, as mentioned previously, it is a lot of hassle. Refrain from choosing a vendor that a-priori does not have the right certificates.

Customization

When two vendors out there have the same product where one has that product as an off-the-shelf product while the other has to do some kind of customization for manufacturing the same product, the off-the-shelf vendor has a very big advantage for a multiple of reasons:

(a). The manufacturing process should already be stable and well established which saves you and your vendor the learning curve pains for a custom-made product.

(b). The vendor will have additional units manufactured quite quickly if a sudden ramp-up is needed since the production capacities were already prepared and established as an off-the-shelf item.

(c). The vendor will be more willing to hold extra stock of that product.

(d). In case of supply shortage when buying directly from the vendor you may find 3rd party vendor\client that may sell you your missing units and solve your immediate issue. This BTW works both ways if for example you end up with too many units on your hands and would like to return them to the vendor or re-sell the items to a 3rd party.

(e). Usually the longevity (see below) of an off-the-shelf product is longer.

This consideration in its self has less weight when you purchase large quantities of the product. When you purchase enough the vendor will, in his own interest, keep its production line available for your item manufacturing. This though does not have a number as it changes from this HW type to another. For example, if we are talking about a peculiar capacitor in electronics that number would have to be millions and even tens of million units annually. However, if we are talking about an aspheric lens, I assume 10,000 units per annum would be enough for the vendor to reserve production line time for you.

Production Capacity & Availability

Adjust your expected quantities per year to your chosen vendor. If you expect 10,000 units per year and that is the total capacity of your vendor there is a good chance that not all the production capacity of the vendor would be at your disposal.

Lead Time

Let’s divide the lead time into samples for initial testing or proof of concept and into mass production. When you need a few samples for testing you want to get them as fast as you can so there is an advantage for samples being delivered within a fortnight. It is so crucial in the R&D process that sometimes you would prefer to start testing on samples delivered quickly by one vendor although the final chosen vendor for the final product will be another. For mass production, the shorter lead time the better.

Item Production Longevity

The longer production longevity commitment by the vendor the better. It should be at least as long as your expected product life cycle, preferably more to withhold support and sustain even after mass production has finished in the life cycle. Make sure to include it in the comparison chart between the vendors.

Production Site Location and Import\Export Conditions

Without going too much into international politics, there are counties that due to reasons that have nothing to do with you or your vendor may impose difficulties in the supply chain. Furthermore, there are sometimes limitations over what kind of products may be supplied to end-clients who reside in certain countries (try to purchase a SWIR camera from a US vendor and integrate it into a medical machine that goes to Asia). The “easier” production site will have an advantage. This particular issue will be handled best by the Supply Chain team.

Vendor’s Supply Chain

Like us, the vendors and manufacturers have their own supply chain. Those vendors that have a bigger portion of their manufacturing process performed inside their own facilities are less prone to delays. Having said that, in some cases the product is in itself an integration of different products and it will be difficult to find a vendor that has everything done in-house. Let’s take for example the camera industry, there are a few leading sensor manufacturers like Sony, Teledyne e2v, ams (CMOSIS) etc. who are the suppliers for the different camera manufacturers, so nearly all camera manufacturers depend on these companies to deliver on-time.

Company Size

When your expected mass production requires 1,000 units per year and the vendor is a 10,000,000 units per month production facility make a note to yourself that you are probably not in this vendor’s top 10 strategic clients. A more modest facility would probably be a more suitable choice for you. Having said that, if you are the vendor’s only client then that may also be a dangerous choice. When your demands are for small to medium quantities, try to find the middle ground between these two extremes.

Legal Matters

A contract with a vendor is a legal document. If you are going to buy some version of an off-the-shelf product probably there won’t be much to the legal but when addressing an R&D project sometimes there is a joint venture to find a solution with the vendor. That is where the legal department comes into play and settles all IP matters as well as other legal matters. In market changing technologies the legal limitations may be the weight shift factor to one vendor or another.

Exclusivity

When a custom design is manufactured for your project, you may ask the vendor for exclusivity i.e. that particular item can be manufactured only for your company and no one else without your explicit approval. The Product Manager of your project should be the function who decides whether this is important for your product market or not.

Support Level

Yes, everyone needs support for their HW. Sometimes because the documentation is not up to standard and sometimes because we would like to use a feature of the HW which is off-the-beaten-track. Support level and responsiveness of the vendor is very crucial especially when you are trying to fix a machine that has already reached the client.

Communication with the Vendor

This wouldn’t be the first item on the list, but good communication with the vendor makes a great difference. If I may quote the purchase director of a company I worked for “when your vendor remembers your name with a positive note, you will get many more things done and get them quicker. If the vendor does not know your name, then you will be just like any other client. If your name comes up on a negative note with the vendor, then you had better be his biggest client”. If you have the choice, do not go to a vendor where there’s bad blood between the vendor and your company.

Price

The cheaper the better, yes, but only if it is a good fit. There are items in your BOM that you would know initially that are price sensitive, so you may plan ahead how to reduce the price either at the end of R&D (2nd generation) or in mass production. Note that pricing is the last item in the list, first because it probably goes without saying and secondly because there are many stakeholders who would pull for the lowest price and force compromises, technical and non-technical. However, if the compromises are accepted very well, you must be very careful of the fine-print.

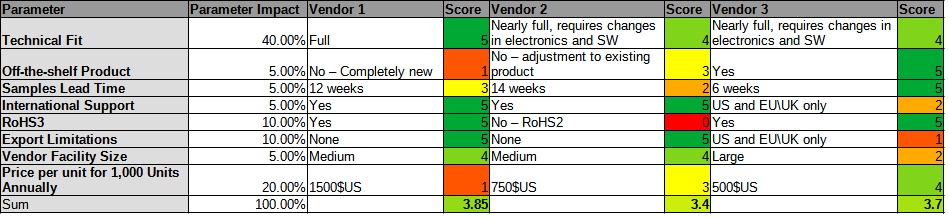

Comparison Table

When comparing vendors, it is advisable to have a comparison chart with the important technical and non-technical relevant items for the discussed product in order to have a fair and objective comparison between the different vendors, as follows:

In the example above there would have been a more difficult decision between the 3 vendors if vendor #2 would have had RoHS3 compliance, but it left the winner as the expensive new and custom made product in the first place and closely after that vendor the off-the-shelf product. The weights are up to the project’s team decision.

That’s all folks ![]() . I could have gone further into different products’ documentation fine details and how to evaluate the gravity of each factor in the agreement with the vendor, but that would be subjective and very industry type specific so no real lesson could be learned from such case studies. I hope the content of this post will help you folks out there, not just in Engineering but also in Purchasing and Supply Chain.

. I could have gone further into different products’ documentation fine details and how to evaluate the gravity of each factor in the agreement with the vendor, but that would be subjective and very industry type specific so no real lesson could be learned from such case studies. I hope the content of this post will help you folks out there, not just in Engineering but also in Purchasing and Supply Chain.